>> 2-Way High

Pressure Ball Valve (Model Code - AHB G - 1/8” to 2”).

DESCRIPTION

Flutec 2-way High pressure Ball Valves are of a compact construction.

- Working temperature depending upon sealing material - 200C to + 2500C

- Easy handling even at high

pressure (switching through 900)

- Working pressure upto 500/1000bar .

- Individual pressure testing ensures safety.

- If the ball valve are to be used for gas, oxygen or any other special application, please give full details when ordering with temparture and pressure.

- Block housing in carbon steel phosphate plated. Other metallic finish on request.

- Are also manufactured in stainless steel & Brass material.

- Are supplied with red powder coated straight aluminium / steel handles.

|

|

>> 3-Way Ball Valve (Model Code-AHB3K - 1/8” to 2”).

DESCRIPTION

Flutec 3-way Ball Valves are of a compact construction..

- Working temperature depending upon sealing material - 200C to +2500C.

- Working pressure up to 500bar.

- Easy handling even at high pressure (switching through 900).

- Individual pressure testing ensures safety.

- If the ball valve are to be used for gas, oxygen or any other special application, please give full details when ordering with temparture and pressure.

- Block housing in steel chrome plated. Other metallic finish on request.

- Are also manufactured in stainless steel & Brass material.

- Are supplied with red powder coated cranked steel handles.

- Size Range : 1/8" to 2"

|

|

>> NEEDLE VALVE/ SHUT OFF VALVE

DESCRIPTION

Flutec 3-way Ball Valves are of a compact construction.

- Flutec Needle Valves are designed for accurate regulation and positive shut-off in impulse and instrument lines and other small line systems.

- Under pressure upto maximum 1000 bar.

- Needle valves are manufactured for all general application i.e. oil, water, gas, steam and other wide range of fluids.

- Individual pressure testing ensures safety.

- The valves are available in carbon steel, SS304, 316, and Brass with BSP/NPT end connections.

- Size Range : 1/8" to 11/2"

|

|

|

|

>> Manifold Block

Mounting Ball Valves(Model code - AHP -10 to 38).

DESCRIPTION

Flutec 2-way High pressure Ball Valves are of a compact construction.

- Flutec manifold mounted Ball

Valve for mounting on to valves Block.

- The Ball valve has a milled slot indicating the setting. The valve is positioned by means of stop pin and stop disc.

- Easy handling even at high pressure upto 350bar(switching through 900).

- Individual pressure testing ensures safety.

- Operating temperature- -200C to +2500C depending upon the sealing material.

- If the ball valve are to be used for gas, oxygen or any other special application, please give full details when ordering with temparture and pressure.

- Housing Steel (Standard model phosphate plated, other metallic finish on request).

- Ball - Stainless steel.

- Red powder coated aluminium / steel handles.

- Sizes from AHP 10 to 38.

|

Model

Code |

A |

B |

C |

D |

E |

F |

G |

ØH |

ØJ |

ØK |

ØL |

| AHP 10 |

70 |

55 |

45 |

40 |

- |

55 |

44 |

9.5 |

15 |

14 |

8.4 |

| AHP 16 |

98 |

60 |

55 |

45 |

41.5 |

83 |

58 |

16.0 |

25 |

14 |

8.4 |

| AHP 20 |

117 |

70 |

70 |

51 |

48.5 |

97 |

69 |

20.0 |

30 |

17 |

10.5 |

| AHP 25 |

135 |

80 |

80 |

60 |

57.5 |

115 |

81 |

23.5 |

35 |

17 |

10.5 |

| AHP 32 |

165 |

100 |

100 |

78 |

68.0 |

136 |

96 |

32.0 |

40 |

19 |

13.0 |

|

|

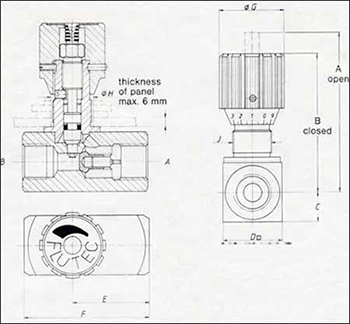

>> Flow Control Valves.

DESCRIPTION

Permits

a simple and accurate control of hydraulic fluid, with increasing

number of turning of the control knob, starting from the closed

position the flow increases evenly. The last turning results in a

complete opening of the flow passage. The flow in the reverse

direction is free. The coloured scale permits a good repetition of

settings and the coloured triangle provides a visible indication of

the flow control valve opening. Increase of the coloured triangle

equals increased flow through the flow control valve. A setscrew is

provided in the side of the knob to lock the flow control valve in

set position to comply with safety standards. |

|

|

|

|

|

| Model Code |

Thread |

A |

B |

C |

D |

E |

F |

G |

H |

J |

SW |

Weight

(kg) |

| TCV-6 |

1/8" |

55 |

50 |

8 |

16 |

26 |

45 |

24 |

13 |

Pg 7 |

- |

0.13 |

| TCV-8 |

1/4" |

72 |

65 |

12.5 |

25 |

33.5 |

55 |

29 |

19 |

Pg11 |

- |

0.30 |

| TCV-10 |

3/8" |

74 |

67 |

15 |

30 |

41 |

65 |

29 |

19 |

Pg11 |

- |

0.45 |

| TCV-12 |

1/2" |

92 |

82 |

17.5 |

35 |

44 |

73 |

38 |

23 |

Pg16 |

- |

0.80 |

| TCV-16 |

3/4" |

106 |

96 |

22.5 |

45 |

57 |

88 |

38 |

23 |

Pg16 |

- |

1.30 |

| TCV-20 |

1" |

145 |

128 |

25 |

50 |

77 |

127 |

49 |

38 |

Pg29 |

19 |

2.40 |

| TCV-25 |

1 1/4" |

150 |

133 |

30 |

60 |

93 |

143 |

49 |

38 |

Pg29 |

19 |

3.50 |

| TCV-30 |

1 1/2" |

155 |

138 |

35 |

70 |

108 |

143 |

49 |

38 |

Pg29 |

19 |

4.60 |

| TCV-40 |

2" |

165 |

148 |

45 |

90 |

130 |

165 |

49 |

38 |

Pg29 |

19 |

7.70 |

|

>> Manifold Block Mounting Flow Control Valves - with Check Valve

(Model Code -TCVP 8 to 40)

DESCRIPTION

Flutec manifold

mounted flow control Valve for mounting on to Block. Permits a

simple and accurate control of hydraulic fluid, with increasing

number of turning of the control knob, starting from the closed

position the flow increases evenly. The last turning results in a

complete opening of the flow passage. The flow in the reverse

direction is free. The coloured scale permits a good repetition of

settings and the coloured triangle provides a visible indication of

the flow control valve opening. Increase of the coloured triangle

equals increased flow through the flow control valve. A setscrew is

provided in the side of the knob to lock the flow control valve in

set position to comply with safety

standards.

|

|

|

|

|

Model

Code |

A |

B |

C |

D |

E |

F |

G |

H |

J |

ØK |

ØL |

ØM |

ØN |

ØP |

| TCVP-8 |

89 |

82 |

63.5 |

50.0 |

30 |

25.5 |

- |

35.0 |

33.5 |

7.0 |

12.7 |

11 |

6.6 |

M18 X 1.5 |

| TCVP-10 |

91 |

84 |

70.0 |

50.0 |

32 |

25.5 |

- |

33.5 |

38.0 |

10.0 |

15.7 |

11 |

6.6 |

M18 X 1.5 |

| TCVP-12 |

113 |

103 |

80.0 |

57.5 |

38 |

30.0 |

- |

38.0 |

44.5 |

13.0 |

18.7 |

11 |

6.6 |

M22 X 1.5 |

| TCVP-16 |

132 |

120 |

104.0 |

70.0 |

45 |

54.0 |

38.0 |

76.0 |

54.0 |

17.0 |

24.5 |

14 |

9.0 |

M22 X 1.5 |

| TCVP-20 |

170 |

153 |

127.0 |

76.5 |

50 |

57.0 |

47.5 |

95.0 |

60.0 |

22.0 |

30.5 |

14 |

9.0 |

M38 X 1.5 |

| TCVP-25 |

175 |

158 |

165.0 |

100.0 |

55 |

79.5 |

60.0 |

120.0 |

76.0 |

28.5 |

37.5 |

18 |

11.0 |

M38 X 1.5 |

| TCVP-30 |

195 |

178 |

186.0 |

115.0 |

75 |

95.0 |

71.5 |

143.0 |

92.0 |

35.0 |

43.5 |

20 |

14.0 |

M38 X 1.5 |

|

>> Flow Control

Valves - without Check Valve

( Model Code -TV 6 to 40).

DESCRIPTION

- Flutec Valves are

designed to provide simple and accurate control of hydraulic

fluids.

- By increasing number of turning

of the control knob, starting from the closed position the

flow increases evenly.

- The last turning results in a

complete opening of the flow passage.

- The coloured scale and coloured

ring in the top of the control knob permits an accurate

repetition of settings and visual indication of the flow

area.

- Increase in the size of the

coloured triangle on the rings corresponds to an increase in

flow area.

- A setscrew is provided in the

side of the knob to lock the flow control valve in set

position to comply with safety standards.

|

|

|

|

|

| Model Code |

A |

B |

C |

SQ. D |

E |

| TV - 1/4" BSP |

89 |

82 |

48 |

30 |

M18 X 1.5 |

| TV - 3/8" BSP |

91 |

84 |

58 |

32 |

M18 X 1.5 |

| TV - 1/2' BSP |

113 |

103 |

68 |

38 |

M22 X 1.5 |

| TV - 3/4' BSP |

135 |

125 |

78 |

50 |

M22 X 1.5 |

| TV - 1' BSP |

170 |

153 |

100 |

50 |

M38 X 1.5 |

| TV - 1 - 1/4' BSP |

180 |

163 |

108 |

60 |

M38 X 1.5 |

| TV - 1 - 1/2' BSP |

190 |

173 |

108 |

70 |

M38 X 1.5 |

|

>> >> Flow Control Valves - without Check Valve

( Model Code -TV 6 to 40).

DESCRIPTION

- Flutec Valves are

designed to provide simple and accurate control of hydraulic

fluids.

- By increasing number of turning

of the control knob, starting from the closed position the

flow increases evenly.

- The last turning results in a

complete opening of the flow passage.

- The coloured scale and coloured

ring in the top of the control knob permits an accurate

repetition of settings and visual indication of the flow

area.

- Increase in the size of the

coloured triangle on the rings corresponds to an increase in

flow area.

- A setscrew is provided in the

side of the knob to lock the flow control valve in set

position to comply with safety standards.

|

|

|

|

|

Model

Code |

A |

B |

C |

D |

E |

F |

G |

H |

J |

ØK |

ØL |

ØM |

ØN |

ØP |

| TVP-8 |

79 |

72 |

47.5 |

46.0 |

20 |

25.5 |

- |

35.0 |

33.5 |

7.0 |

12.7 |

11 |

6.6 |

M18 X 1.5 |

| TVP-10 |

84 |

77 |

50.0 |

50.0 |

25 |

25.5 |

- |

33.5 |

38.0 |

10.0 |

15.7 |

11 |

6.6 |

M18 X 1.5 |

| TVP-12 |

99 |

89 |

75.0 |

57.5 |

25 |

30.0 |

- |

38.0 |

44.5 |

13.0 |

18.7 |

11 |

6.6 |

M22 X 1.5 |

| TVP-16 |

113 |

103 |

93.5 |

70.0 |

30 |

54.5 |

38.0 |

76.0 |

54.0 |

17.0 |

24.5 |

14 |

9.0 |

M22 X 1.5 |

| TVP-20 |

165 |

148 |

111.0 |

76.5 |

45 |

57.0 |

47.5 |

95.0 |

60.0 |

22.0 |

30.5 |

14 |

9.0 |

M38 X 1.5 |

| TVP-25 |

165 |

148 |

143.0 |

100.0 |

45 |

79.5 |

60.0 |

120.5 |

76.0 |

28.5 |

37.5 |

18 |

11.0 |

M38 X 1.5 |

| TVP-30 |

170 |

153 |

171.0 |

115.0 |

50 |

95.0 |

71.5 |

143.0 |

92.0 |

35.0 |

43.5 |

20 |

14.0 |

M38 X 1.5 |

|

|